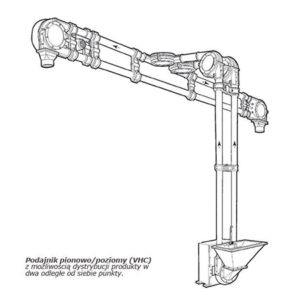

Aero Mechanical Conveyor (disc-in-tube conveying technology)

Applications:

- disc-based conveying of powders and granular materials (minimal damage to friable or sensitive products),

- products commonly handled by AMCs: potato crisps, coffee, tea, suggar, spices, milk powder, animal food, frozen foods, sodium, calcium, fluorine, aluminium, PVC, etc.,

- industries: building products, chemical, cosmetics, food, etc.

Aerosol precipitators

Specification:

- Economical aerosoles removal (smaller than 1 µm):

- odour reduction,

- alternative to fabric filter,

- thermal processes,

- recycling of products.

Auto Rota-shuttle for bridging and caking products

Applications:

- removal of smaller contaminations (rust, filings, etc.) from dry or moist bulk materials,

- used when the majority of contaminations is too small for primary separators,

- removing metal particulars from foods, pharmaceuticals or chemicals.

Auto Shuttle

Applications:

- removal of smaller contaminations (rust, filings, etc.) from dry or moist bulk materials,

- used when the majority of contaminations is too small for primary separators,

- removing metal particulars from foods, pharmaceuticals or chemicals.

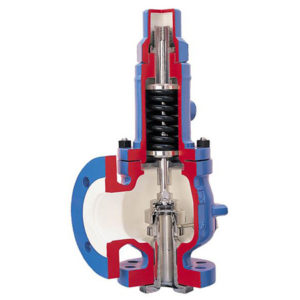

Bailey / Birkett Safety Valves

Applications:

- protection against system overpressure on a wide range of applications.

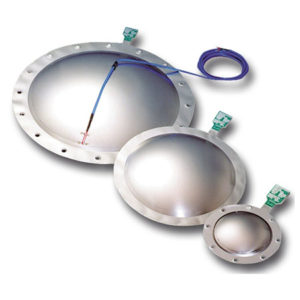

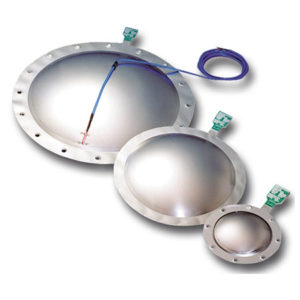

BT-ODV(U), BT and BT-VSI Triple-Section Bursting Discs

Applications:

- protection against excessive pressure and vacuum increase through explosion relief

Butterfly Valves

Applications:

- powders, dusts, liquids, gases,

- potentially flammable powders and bulk solids,

- suitable for use in explosion hazard areas,

- control, shut-off and dosing of powders and bulk solids.

Catalytic reduction of NOx and dioxins (SCR) in waste gases

Application:

- reduction of nitric oxides NOx and dioxins/furans (PCDD/PCDF),

- application for both raw and pure gases in installations for treatment of municipal wastes as well as installations for treatment of hazardous products.

CBBS Type Cross Belt Bucket Sampler

Applications:

- collects representative samples of biomass and/or coal directly from transfer chutes of belt conveyors,

- biomass sampling for the purpose of financial settlement between power plants and the Energy Regulatory Office – accounting for rebewable energy,

- taking samples for the purpose of financial settlement between power plants and coal/biomass suplpiers.

Central Vacuum Cleaning Systems

Applications

Industrial centralised vacuum cleaning systems are used for removing dust buildup from floors, flat surfaces, plant, machinery and structural elements of facilities. This solution is also used as local dust extraction stations at workplaces with high and directional dust emissions. Extraction hoods and extensions are provided for this type of setup.

Standard central vacuum cleaning systems are designed for free-flowing, dry, non-agglomerating and non-explosive dusts.

Explosion protected central vacuum systems are used with potentially explosive dusts and include certified explosion certified equipment for application in relevant explosion zones (as required by the customer) and the necessary explosion protection system (explosion suppression, venting and isolation). Our services may also include preparation of an Explosion Assessment Document, or an Explosion Protection Document.

CONDUX CGS Fluidized Bed Jet Mill

Applications:

- the fluidized bed jet mill with an air classifier is suitable for fine grinding of dry materials within the range of d97 = 2 µm to d97 = 70,

- suitable with a large range of materials of any hardness,

- possible applications: activated carbon, dental ceramics, graphite, ceramic pigments, ceramic catalysts, silica, pesticides, talc, toner, wax, tungsten carbide, glass, mica, iron oxide.

CONDUX ConJet® High-Density Bed Jet Mill

Applications:

- this spiral jet mill with an integrated classifier wheel is perfect for grinding dry materials within the range of d97 = 2.5 µm to d97 = 40,

- suitable with very hard materials,

- possible applications: pigments, pharmaceuticals, toner, talc, silica, aluminum oxide, barium titanate, chromium carbide, tungsten carbide, limestone, graphite, cosmetic powder, metal powders, plant protection products.

CONDUX CP Impact Mill

Applications:

- grinding and classification in the range from 20 to 150 μm,

- possible applications: pigments, gelatine, wheat, charcoal, limestone, synthetic coatings, sodium carbonate, sulphate, phenolic resin, coating powder, talc or toner.

CONDUX CS-Z Cutting Mill

Applications:

- size reduction by cutting of non-friable and soft products in a range of 90–2000 μm,

- possible applications: cellulose, wood fibers, rubber, scrap paper, leather, textiles, carbon fibers, PES film, TPU, unvulcanized rubber.

CONDUX CSM Classifier Mill

Applications:

- grinding and classification from d97 10 µm to d97 150 µm,

- possible applications: sugar, pigments, gelatine, cereals, cocoa press cake, limestone, potato starch, silica, sodium bicarbonate, polyacrylamide, coating powder, silica gel, soy protein, tobacco, talc, toner, wheat gluten.

CONDUX CUM Universal Mill

Applications:

- suitable for materials with Mohs hardness 3-3.5 in a range of 30-1500 μm,

- possible applications: sugar, spices, soot, cork, corn starch, grain, gluten, graphite, plastic, cosmetic products, sodium carbonate, ammonium chloride, calcium carbonate, sodium nitrate, talc, urea.

Conveying-screening gutter

Application:

- possibility of conveying and proportioning of loose materials during screening,

- dewatering of wet products.

Conveyor Head Roller

Applications:

- elimination of larger contaminant particles (typically including nails, screws, nuts, etc.) from powders and bulk solids,

- protection of machines and equipment from damage,

- elimination of potential sources of ignition (fire and explosion protection),

- conveyor belts, transfer chutes, pneumatic conveying lines.

Cylindrical compactors

Application:

- conversion of powder form into granulate with controlled particle size, e.g. to limit segregation of mixtures with various densities during transport,

- improvement of flowing capabilities and dosage of loose materials,

- limiting abrasion during transport of materials with abrasive properties,

- elimination of dusting during operations of mixing, dispergation, etc.,

- form of loose materials accepted by the market (no dusting).

DA/DA-VS Vacuum Deaerator

Applications:

- food (sirups, drinks, ketchup, nut butter),

- pharmaceuticals and cosmetics (liquid soap, shampoo, toothpaste, detergents),

- chemical products (paints & coatings, adhesives, sealants, lubricants, latex compounds).

Deep Field Chute

Applications:

- elimination of larger contaminant particles (typically including nails, screws, nuts, etc.) from powders and bulk solids,

- protection of machines and equipment from damage,

- elimination of potential sources of ignition (fire and explosion protection),

- conveyor belts, transfer chutes, pneumatic conveying lines.

Deep Field Plate for overband installation

Applications:

- elimination of larger contaminant particles (typically including nails, screws, nuts, etc.) from powders and bulk solids,

- protection of machines and equipment from damage,

- elimination of potential sources of ignition (fire and explosion protection),

- conveyor belts, transfer chutes, pneumatic conveying lines.

Deflagration Flame Arresters

Applications:

- suitable for use in systems where deflagration may occur (explosion propagating at subsonic velocity),

- prevents propagation of flames in gas or vapour mixtures,

- suitable for use in all explosion classes,

- suitable for use in-line or end-of-line,

- storage tanks with flammable liquids,

- transport of flammable gasses, vapours and liquids,

- chemical processing plants and oil refineries,

- fuel, oil or biogas depots.

Detonation Flame Arrester

Applications:

- suitable for use in systems where detonation may occur – either unstable(during the transition of a combustion process from a deflagration into a stable detonation and where the explosion pressure is significantly higher than in a stable detonation) or stable (when it progresses through a confined system without significant variation of velocity and pressure characteristics),

- prevents propagation of flames in flammable gas or vapour mixtures,

- suitable for use in all explosion classes,

- suitable for use in-line,

- storage tanks with flammable liquids,

- transport of flammable gasses, vapours and liquids,

- chemical processing plants and oil refineries,

- fuel, oil or biogas depots.

DG-IR-3C Infrared Detector

Applications:

- a protection system element to be installed in ducts and pipelines connected to bucket conveyors, filters, tanks and other equipment for immediate detection of explosion events,

- identification of ignition sources such as flame, heat and sparks in order to activate the protection system on process lines and ducts connected to protected equipment,

- quick detection of an explosion propagating through ducts and piping in order to activate the protection system,

- to be used in enclosed areas without daylight access.

Diverter Valves

Applications:

- pneumatic conveying systems for powders and bulk solids,

- also suitable for gas applications.

Drum driers

Application:

- processes: drying, cooling, heating,

- materials: fertilizers, minerals, chemical substances, food products (fruits, vegetables), granulated or dusty solid products, industrial solid wastes, limestone, ores, oxides, dolomites, talc, rubber, fibers,

- possibility of independent operation or in combination with a rotary drier (final drying) or fluidal vibration dryer (difficult product).

Drum dryer

Applications:

- food, chemical and pharmaceutical industries,

- drying sticky and high viscosity products,

- drying low viscosity products,

- vacuum drying (temperature-sensitive products),

- vitamins, proteins, instant beverages, baby food, chocolate products, solvent recovery, soap,

- for recovery of salt from waste streams (NaCl, (NH4)2SO4).

Drum Flaker

Applications:

- solidification of molten substances into flakes or microcrystals,

- food, chemical and pharmaceutical industryies.

Dual-shaft helical granulator / Pug Mill (mixing, granulation)

Application:

- processes: mixing, granulation,

- operation in the presence of urea, water vapor, sulfuric acid, ammonia.

Dust Collection Systems

Applications

The basic purposes of dust control systems are:

- to reduce dust concentrations in the workplace to levels that are not considered harmful to human health,

- to clean gases to safe levels before they are released to the atmosphere,

- to reduce dust concentrations in order to eliminate or reduce the need for explosion hazard zones in the workplace.

Dynamic wet scrubbers

Specification:

- Removal of submicron particulates,

- Economical pollutant removal,

- High gas volume flows,

- Low maintenance demand,

- Self-cleaning wet fan.

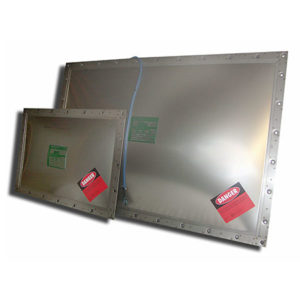

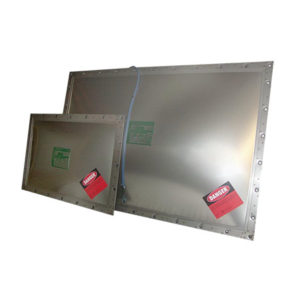

EDP Single-Layer Explosion Relief Panel

Applications:

- protection of vessels and equipment from explosion effects (silos, cyclones, filters),

- can be installed on systems with minor working pressure fluctuations,

- suitable for pharmaceutical, food and sterile applications, SIP/CIP cleaning capability.

ERO Single-Layer Burst Panel

Applications:

- protection against overpressure and dynamic explosion pressure rise by explosion relief,

- suitable for sanitary, food, pharmaceutical and other sterile applications.

Evaporation & Crystallization

Scope of supply:

- evaporators, concentration systems and crystallizers (water vapor, operation under vacuum),

- heat exchangers, condensers, distillation columns, degassers,

- auxiliary equipment (filters, centrifuge, driers),

- stripping columns (control and elimination of odors),

- non-waste installations for treatment of liquid sewage in power industry, refineries.

EX 100.1 Single-Zone Control Unit

Applications:

- control unit for an explosion protection system (HRD containers, pressure and infra-red detectors),

- this single-zone control unit performs the following control and diagnostic functions: system monitoring, distribution of stored energy for actuation of explosion-protection equipment and on-line verification of the status of an explosion suppression system.

EX 8000 / EX 5000 Multi-Zone Control Unit

Applications:

- control unit for an explosion protection system (HRD containers, pressure and infra-red detectors),

- this multi-zone control unit performs the following control and diagnostic functions: system monitoring, distribution of stored energy for actuation of explosion-protection equipment and on-line verification of the status of an explosion suppression system,

- its modular design allows selective system activation (e.g. system activation for a single piece of equipment in which an explosion occured).

EX-GO-VENT (EGV) Single-Layer Burst Panel

Applications:

- protection of various types of vessels from explosion effects through explosion relief,

- silos, cyclones, filters, etc.

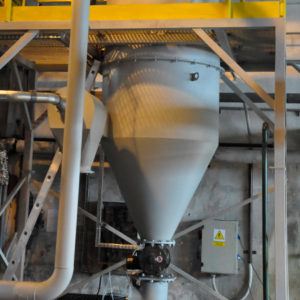

ExKop Explosion Isolation and Venting System

Applications:

- protection of filters, mixers, cyclones, mills, dryers and other process equipment as well as preventing the transfer of explosion effects to the rest of the plant area or equipment.

Explosion Isolating Rotary Valve

Applications:

- certified for application in explosion hazard areas,

- the valve can be mounted on the outlet of filters, cyclones, silos, conveyors and other process equipment,

- suitable for dosing and direct installation in a pneumatic conveying system.

Explosion Venting On Ducts and Pipelines – STT Type Diverter

Applications:

- protection against propagation of explosion from processing equipment (e.g. mills) to silos, filters or electrostatic precipitators by controlled venting of explosion effects to the atmosphere (explosion isolation) and/or,

- protection against explosion propagation from silos, filters or electrostatic precipitators to the plant’s process equipment by controlled venting of explosion effects (explosion isolation).

FP Chute Sampler

Applications:

- collects representative samples of biomass and/or coal directly from a free falling flow of material,

- biomass sampling for the purpose of financial settlement between power plants and the Energy Regulatory Office – accounting for rebewable energy,

- taking samples for the purpose of financial settlement between power plants and coal/biomass suplpiers.

G1 Pressure Equalization Valve

Applications:

- protection against overpressure and/or excessive vacuum while filling or emptying vessels,

- storage systems for bulk solids.

G2 Pressure Equalization Valve in High Grade Steel

Applications:

- protection against overpressure and/or excessive vacuum while filling or emptying vessels,

- storage systems for bulk solids.